DNC (Dynamic Noise Control) is a device for the chiller noise reduction: it enables the measurement of the noise produced by the chiller and that adapts the performance of the chiller in order to not exceed the noise constraints and to provide always a very quiet running.

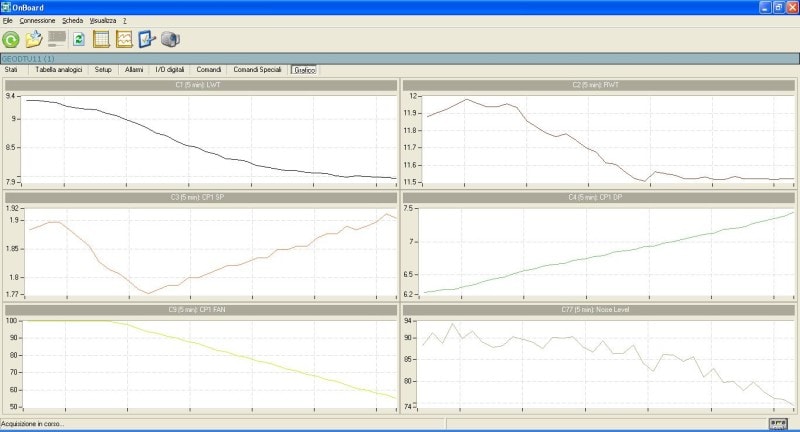

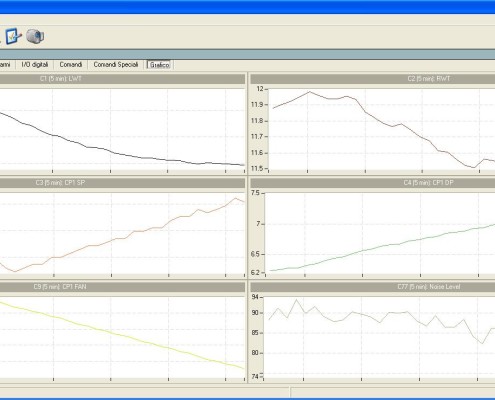

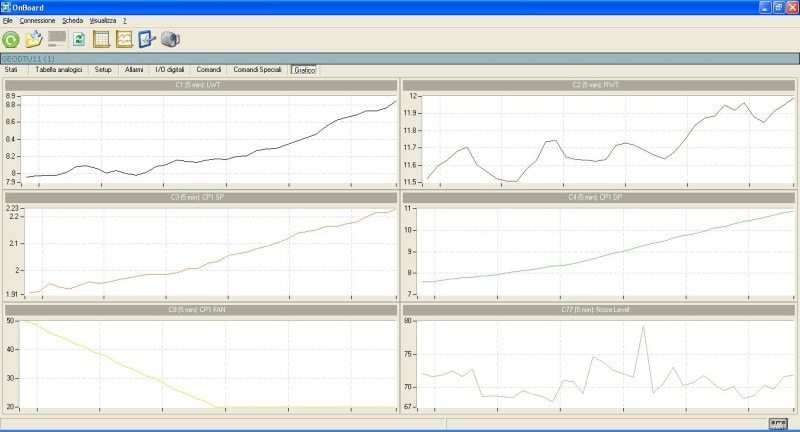

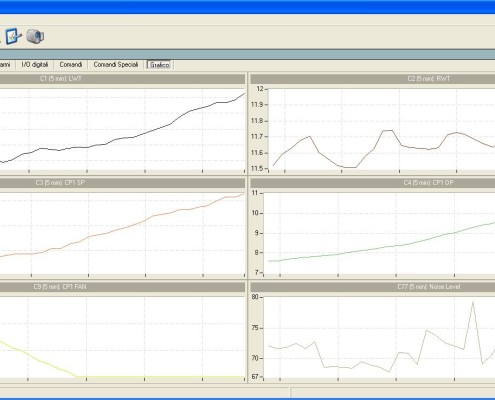

Traditional sound control devices are set up to reduce the noise levels and, as a result of this, the performance, in specific time slots. The weak spot of these systems is represented by the impossibility of adjusting the performance levels on the basis of the actual noise emissions generated by the chiller: as a consequence, there may be a reduction in performance even when it is not necessary.

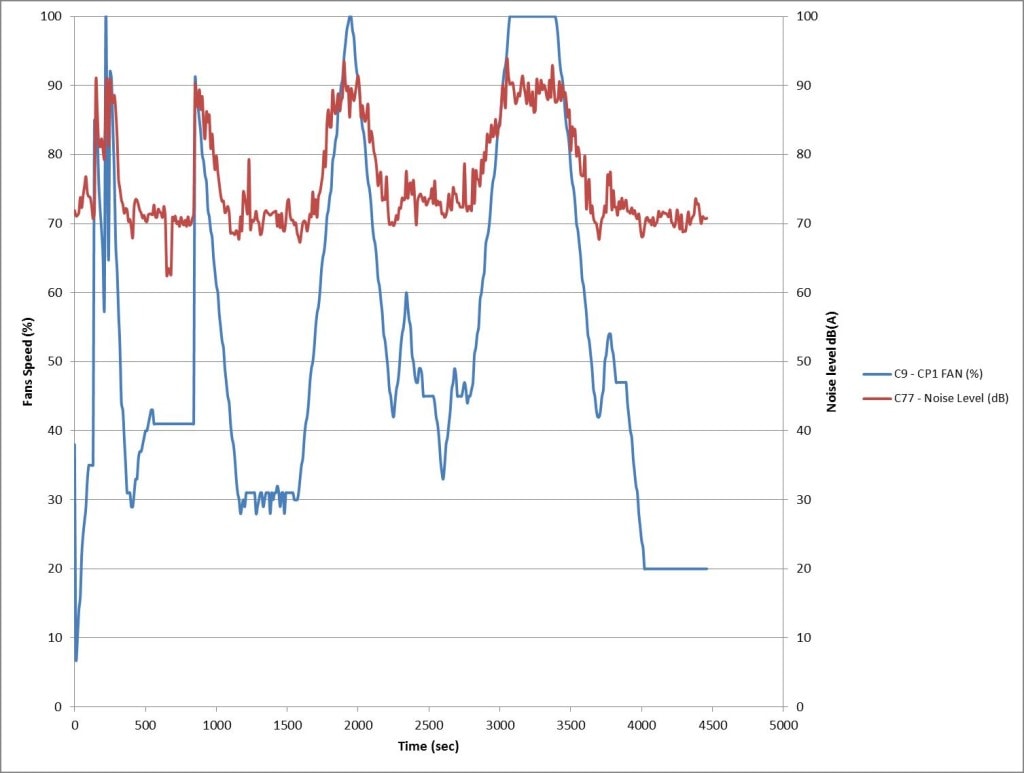

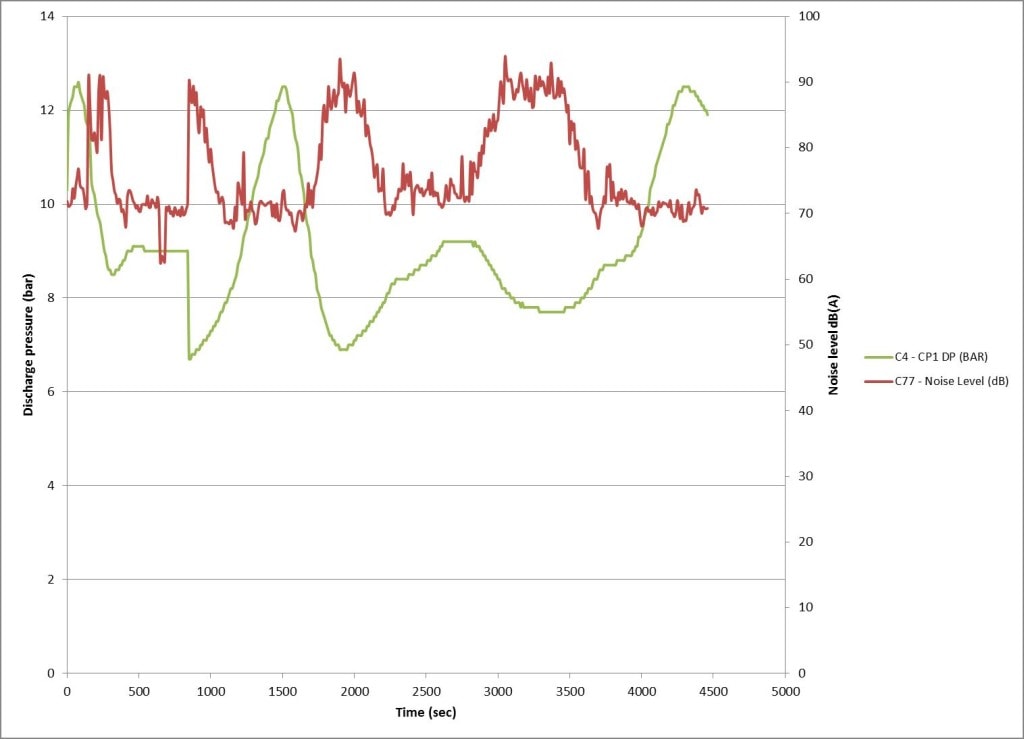

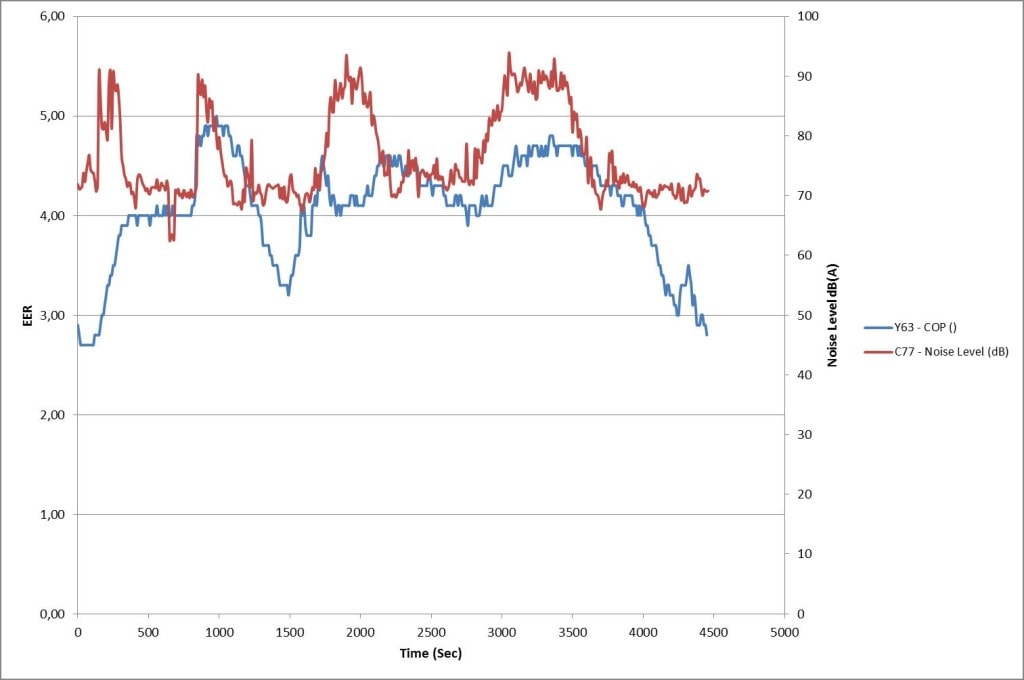

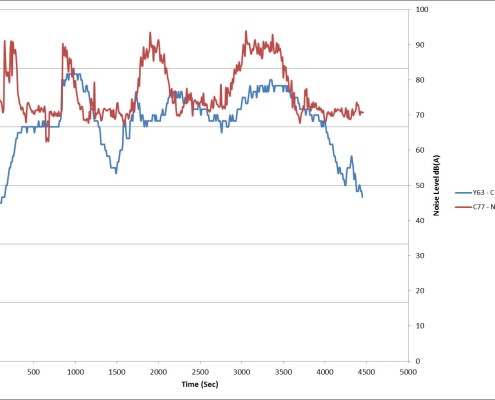

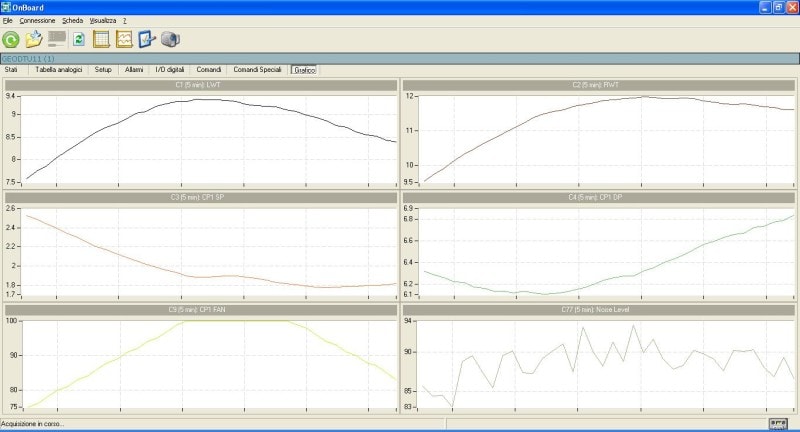

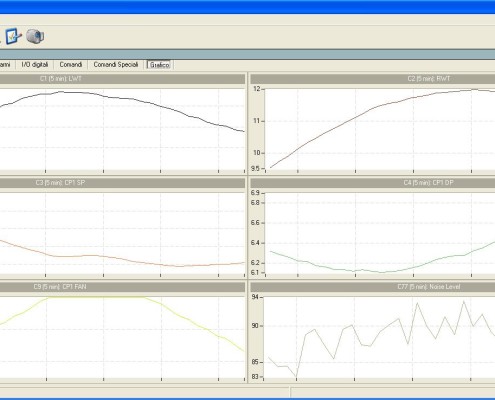

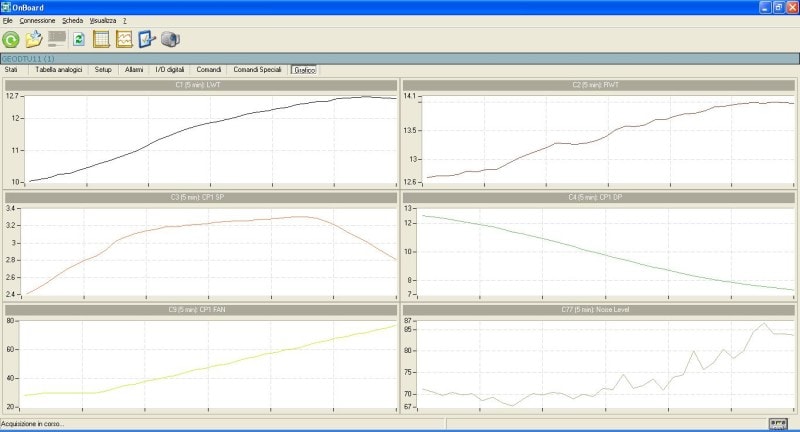

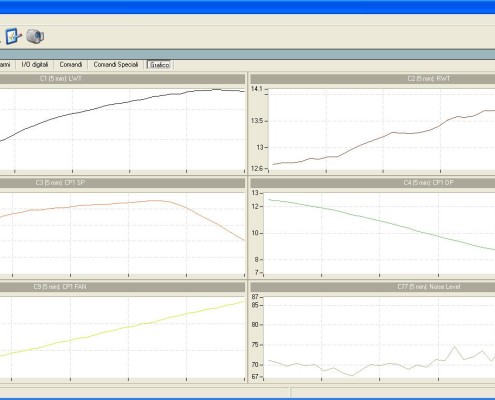

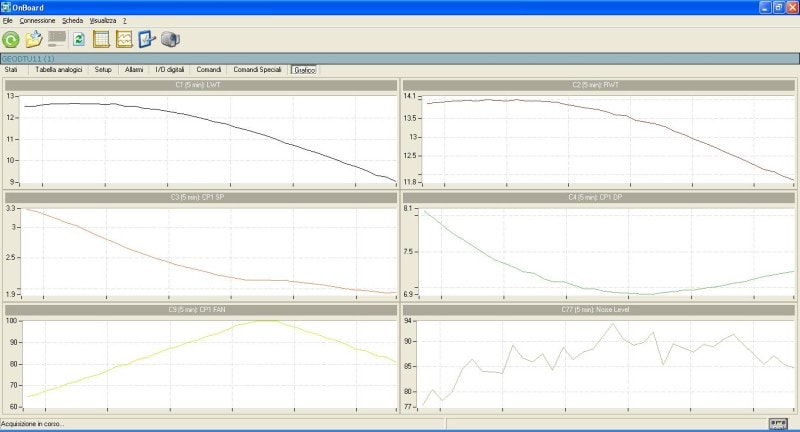

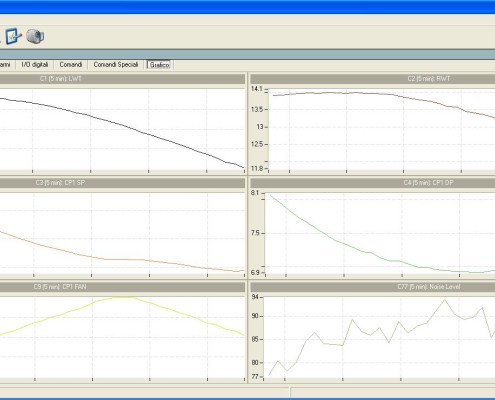

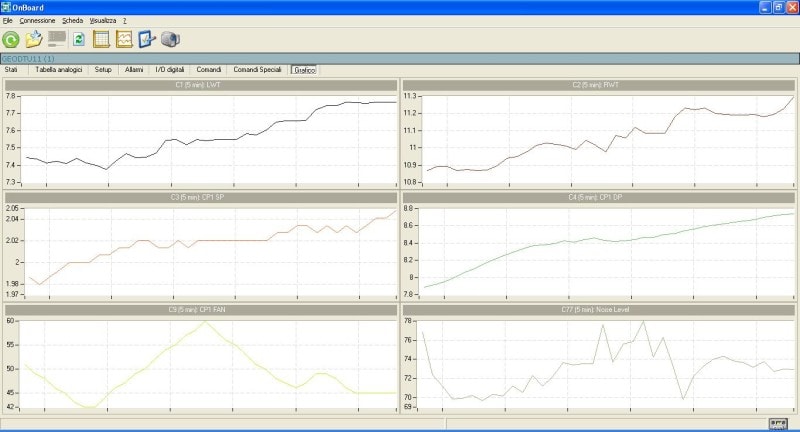

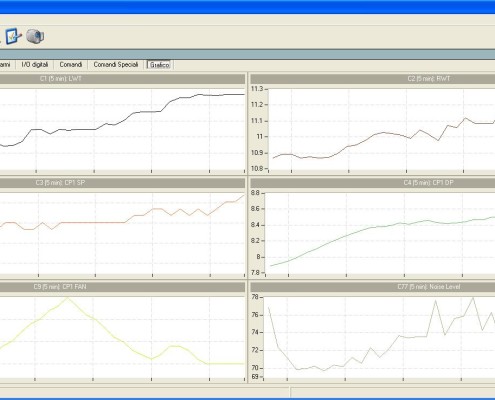

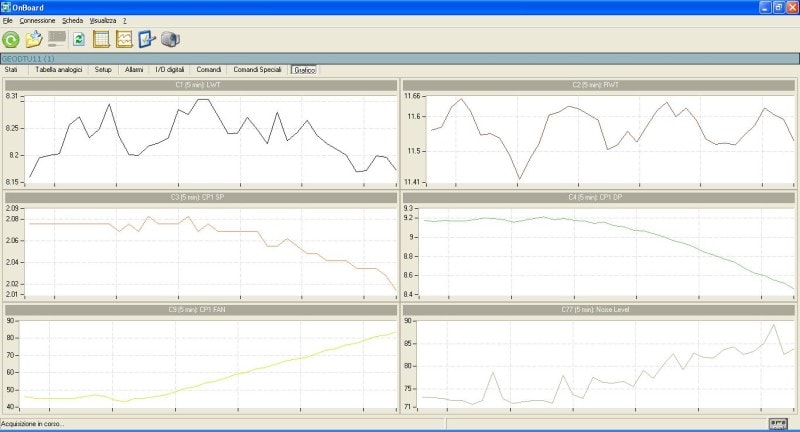

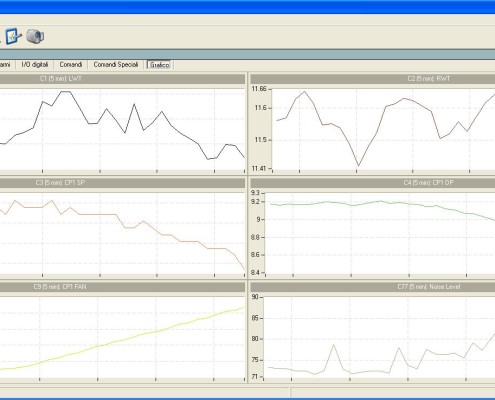

The DNC is designed to avoid this problem: it is designed to be “smart”. The system constantly measures the noise produced by the chiller and is able to “adapt” the chiller performance in order to not exceed the noise limits set for different time slots. The main difference between DNC and other systems consists in the fact that with the Dynamic Noise Control what must be set are only the noise limits, and not the performance levels: it is the DNC that regulates the fan speed, reducing the performance in order to fall within the highest permissible noise level. The DNC is also able to identify the noise source and “understand” if it is generated by the chiller or by any external source. This is a very important aspect that helps to ensure precision and reliability to the entire plant.

The system consists of a microphone and sound processing system mounted on the chiller or at a suitable remote location from the chiller (say, in the direction of residential buildings), and is linked and integrated into the chiller controls. The DNC is designed to be installed also on existing units and for any kind of application. Though it reduces the performance of the unit, the cooling capacity remains unchanged, ensuring constant operation and high reliability.

The system consists of a microphone and sound processing system mounted on the chiller or at a suitable remote location from the chiller (say, in the direction of residential buildings), and is linked and integrated into the chiller controls. The DNC is designed to be installed also on existing units and for any kind of application. Though it reduces the performance of the unit, the cooling capacity remains unchanged, ensuring constant operation and high reliability.

In conclusion, the DNC device, unlike all other traditional sound control devices, whilst reducing the noise emissions, is able to ensure the highest relative efficiency.

The result of the chiller noise reduction is the increase of acoustical comfort and the optimization of the cooling plant with better efficiency when compared to units with fixed fan speed limitation on time slots.