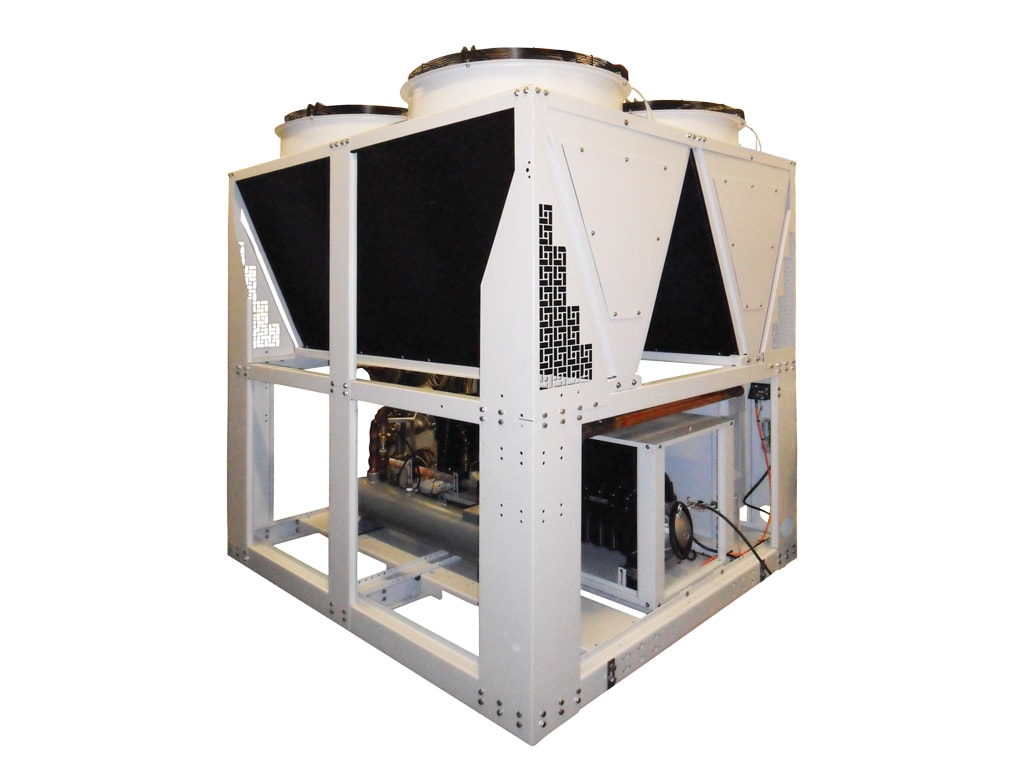

Turbomiser from Geoclima is the most efficient chiller of its type on the market today: thanks to the use of Turbocor compressors, it is able to reduce energy costs by up to 50% compared with traditional units that use screw or reciprocating compressors. Turbomiser chiller has won several awards, including CIBSE, the most prestigious award for technology with low environmental impact.

In addition to ultra-efficient performance, Turbomiser improves comfort and productivity levels in buildings thanks to its innovative design and continuous monitoring. And, with its frictionless magnetic bearings, service and maintenance costs are significantly reduced.

The Turbomiser chiller is based on a combination of technologies designed to reduce energy consumption, minimise or avoid leaks, reduce refrigerant charge and ensure reliable operation and deliver quiet running:

- inverter-controlled magnetic bearing compressors whose output can be precisely matched to load;

- micro-channel aluminium condensers, which reduce refrigerant charge while increasing the effectiveness of heat exchange;

- flooded evaporators, which ensure optimum heat transfer between refrigerant and water;

- the use of a pumping system of the refrigerant, which significantly increases thermodynamic efficiency throughout the entire operative range of the unit;

- inverter driven condenser fans to match performance to demand and reduce energy consumption;

- a sophisticated chiller control system which integrates with that of the on-board integral compressor control to optimise performance of the system as a whole.

Refrigerants

![]()