Background

Evonik is one of the world’s leading specialty chemicals companies, operating in the business areas of chemicals, energy and real estate. Evonik employs about 33,000 people and carries out activities in more than 100 countries.

Purposes

The project concerned the replacement of the R22 chiller installed at the Evonik cooling tower in Essen with a new chiller that had to meet specific requirements in terms of efficiency and environmental impact.

Project

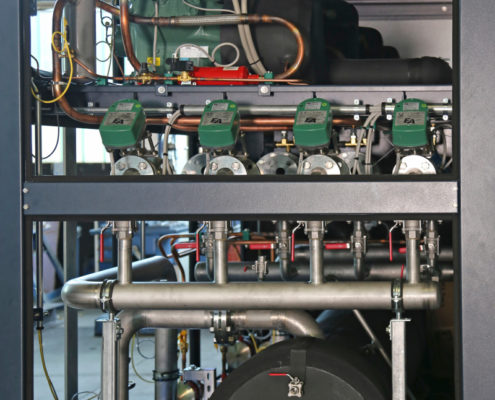

For this project the CROM and Geoclima R&D department designed one chiller with special heat exchangers. The chiller is a 154 kW water cooled VHH unit with four separate cooling circuits and R1270 as natural refrigerant.

The amount of refrigerant has been significantly reduced from 600 kg of R22 in the pre-existing plant to 32 kg of R1270 in the new chiller: R1270 provides high performance and at the same time ensures low environmental impact with a GWP=3.

CROM has produced Titanium-stabilised stainless steel heat exchangers. This special steel is specifically recommended for application in the chemical industry as it reduced the risk of corrosion and does not require any thermal treatment after welding.

There are many residential buildings in the area around the plant, therefore the noise impact had to be minimized and kept below 74 db (A).

The chiller has been completely “closed” in a frame made of removable panels that facilitate the access and maintenance operations on the units. The chiller has been then installed within a special container provided by the client and connected to a special leak detection system, to further improve security level. Also from a structural pint of you, then, the project has required special and accurate design, in order to meet specific requirements in terms of space and security.

Results

The new chiller provided by Geoclima meets all specific requirements and ensures high efficiency, great reliability and low environmental impact.