An overview of refrigerants: the choices for the future

Historical background

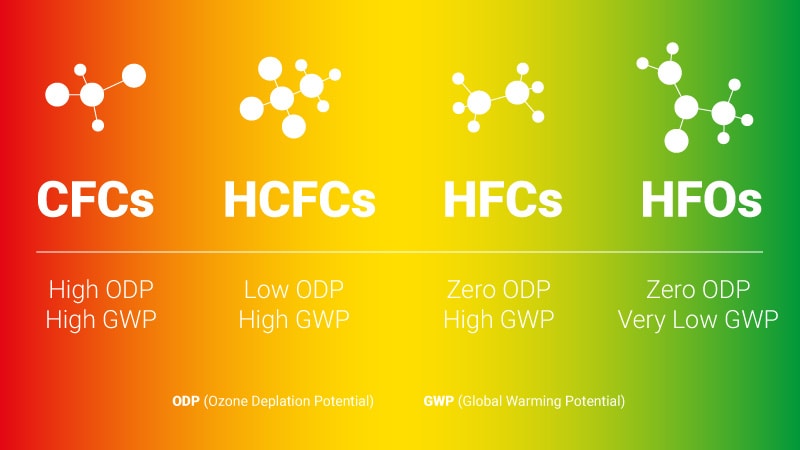

In the first half of the last century, new, more chemically stable refrigerants, with good thermodynamic properties, non-toxic and non-flammable, were introduced to the market. Too bad that environmental aspects were not considered until the 1970s. In fact, these new refrigerants, CFCs and HCFCs, used chlorine and fluorine in large quantities. Unfortunately, it was discovered that these elements contributed significantly both to the depletion of atmospheric ozone and to the formation of the greenhouse effect.

Montreal Protocol and subsequent restrictions

The environmental emergency led to a global agreement, known as the Montreal Protocol (1992), for the phasing out first of CFCs and later of HCFCs. After that, over the years, other agreements and regulations have followed, both internationally and nationally, with further restrictions on the use of gases with a high impact on the greenhouse effect. Hence, the adoption of the GWP (Global Warming Potential) index, a universally recognized parameter that allows you to identify whether the liquid is more or less sustainable from an environmental point of view. At the EU level, the 2030 target was also set to reduce the use of HFCs by 79% compared to 2010.

The HFOs

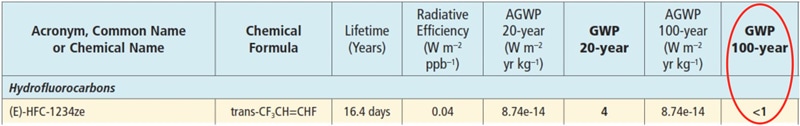

In this context, a new range of refrigerant products with very interesting characteristics has been developed. The HFOs, in fact, maintain a high efficiency and at the same time significantly reduce the environmental impact, as their molecules decompose very quickly in the atmosphere, resulting in a very low GWP. Furthermore, these refrigerants have been classified A2L according to the ASHRAE 34 standard, i.e. non-toxic and mildly flammable. In fact, they need at least 1000 times more energy to ignite than hydrocarbons, and the burning velocity is so low that, in the event of ignition, the flame will spread very slowly and self-extinguish. These features make the HFOs a safe choice in a wide range of applications (refrigeration, air conditioning, heat pumps).

*A2L and B2L are lower flammability refrigerants with a maximum burning velocity <10 cm/s

At Geoclima, we immediately believed in the potential of this innovation: in 2012 we produced the world’s first chiller with HFO-1234ze (GWP <1, according to a 2015 IPCC report) marketed by Honeywell. Our choice was motivated by both ethical and commercial reasons. We are convinced, in fact, that if we consider all the technical requirements that a refrigerant gas must have today, the HFOs represent the best combination of performance, safety, costs and environmental benefits.

Some examples of HFO projects:

Our Reference List with HFO projects:

“Natural” refrigerants

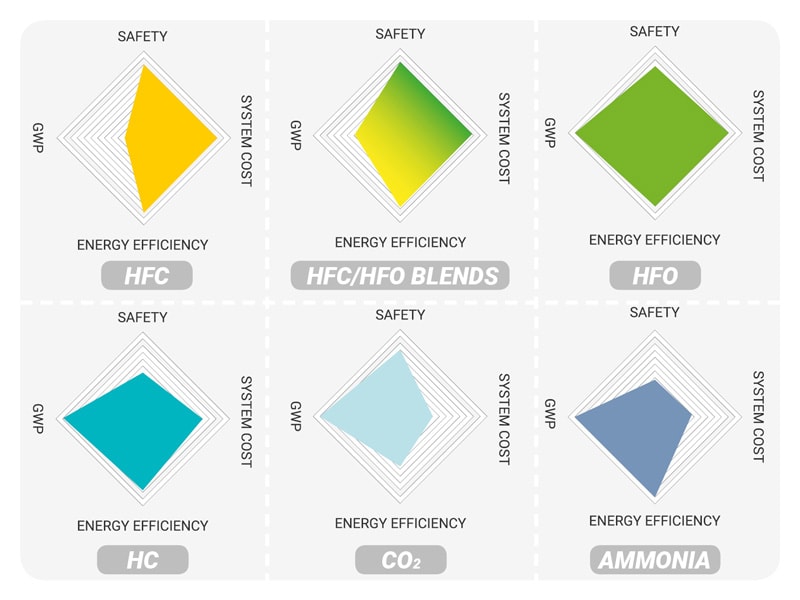

From an environmental point of view, an alternative to the HFOs is represented by industrial chemicals such as hydrocarbons (eg propane and butane), CO2 and ammonia. These chemical refrigerants have very low GWP levels (0 to 4) and are referred to as “natural” since the named substances can be found in nature. Paradoxically, they were the first refrigerants used at the turn of the last century, but because they presented some issues related to sanitary standards, safety, storage, use and disposal, they were replaced with CFCs and HCFCs. Hydrocarbons, for example, have excellent thermodynamic properties, are green, but being very flammable they must be used in systems with a specific design. However, over the years, the technology and knowledge of designers and technicians have evolved to the point that today it is increasingly common to find hydrocarbons loaded in small systems (domestic refrigerators, residential air conditioners), CO2 in commercial refrigeration systems and ammonia in industrial installations.

Our Reference List with natural refrigerants projects:

What about tomorrow?

The new increasingly restrictive environmental provisions are marking the fate of HFCs and their gradual elimination. The future landscape will certainly be dominated by the HFOs; by HFC/HFO blends that exploit the advantages of both technologies to provide the best performance profile based on lower GWP, low flammability, efficiency and ease of use; finally, by a sort of return to origins with the increasingly widespread use of natural gas, thanks to advanced technological solutions and new safety standards.