Background

The client is one of the leading international warehouse manufacturer. In particular, he dealt with the development of one of the biggest warehouse for potatoes storage in the world, located in India.

Purposes

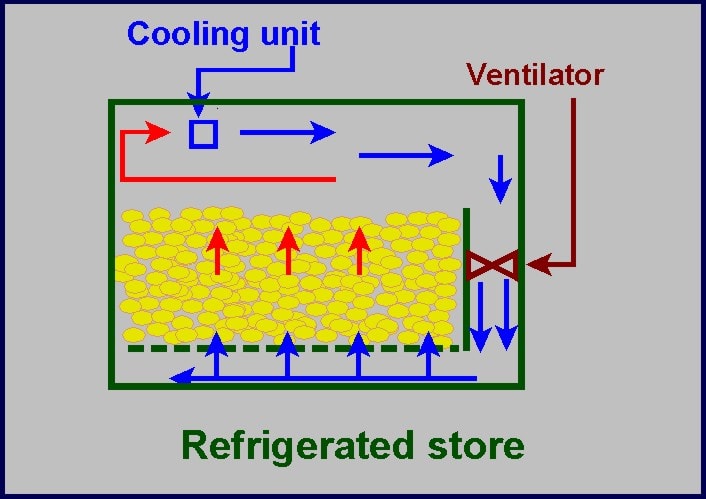

The objective was the development of a highly efficient warehouse, taking into account the several problems concerning the storage and the conservation of potatoes. The first issue was about the high consumption of energy necessary for the operation of the plant. Another important issue concerned the necessity to remain within a very narrow temperature range, relating to the specific potatoes storage conditions. Moreover, the different uses of potatoes require different temperatures (from 4 °C to 10 °C) and this results in the necessity of a dual set point. Finally, there was the need to develop a plant able to control sudden changes of temperature caused by different conditions, such as: external climate variations; interventions within the warehouse (opening/closing of doors, etc.); the tendency of tubers to vegetate or ferment. There was also the need to consider that we were dealing with perishable and edible products and, therefore, it was required to keep within strict conservation rules.

Project

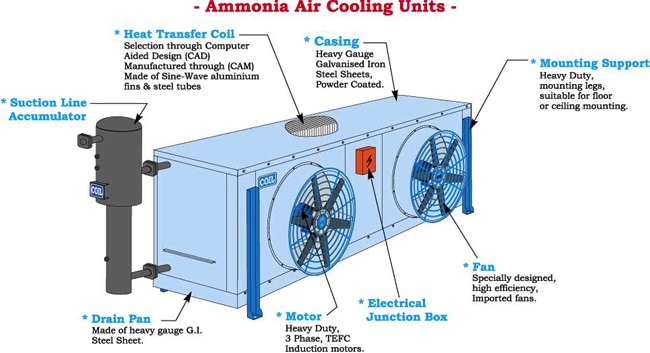

Geoclima proposed a solution combining in a chiller the following technologies:

- aluminium multi-channel batteries

- EC fans

- open screw compressors

- refrigerant R717 (Ammonia)

- propylene glycol

- “microsmart” microprocessor for unit control and regulation

Geoclima was also able to provide to the client an application with low noise levels and to adapt its dimension to the site of installation, ensuring not only very high efficiency but also consistent performance.

Results

Geoclima has designed the plant together with the builder of the warehouse, thereby developing a machine able to satisfy the client’s specific requirements, with great attention to issues concerning the peculiar sector. This solution can be worldwide applied.