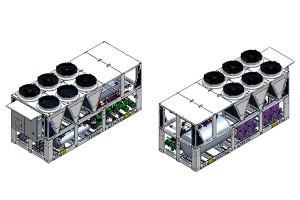

Advanced technology to improve your experience

The Geoclima R&D Department is always committed to studying and developing new solutions to improve our clients’ experience. Quality, efficiency and reliability are the foundations of our engineering and updating processes.

From hardware equipment, such as the DNC and Evaporative System, to software technologies, such as Geoselectool, Geotouch and Onboard Touch, every single product is developed to improve end users’ experience and to provide a comprehensive service that clients can test on their own, from chiller selection to unit control.

All these services are summed up in a new section on the Geoclima website with in-depth descriptions of how these products work: DNC, Evaporative System and Geoselectool pages are already online, whereas Geotouch and Onboard Touch are under construction.

Discover the Geoclima smart technologies!